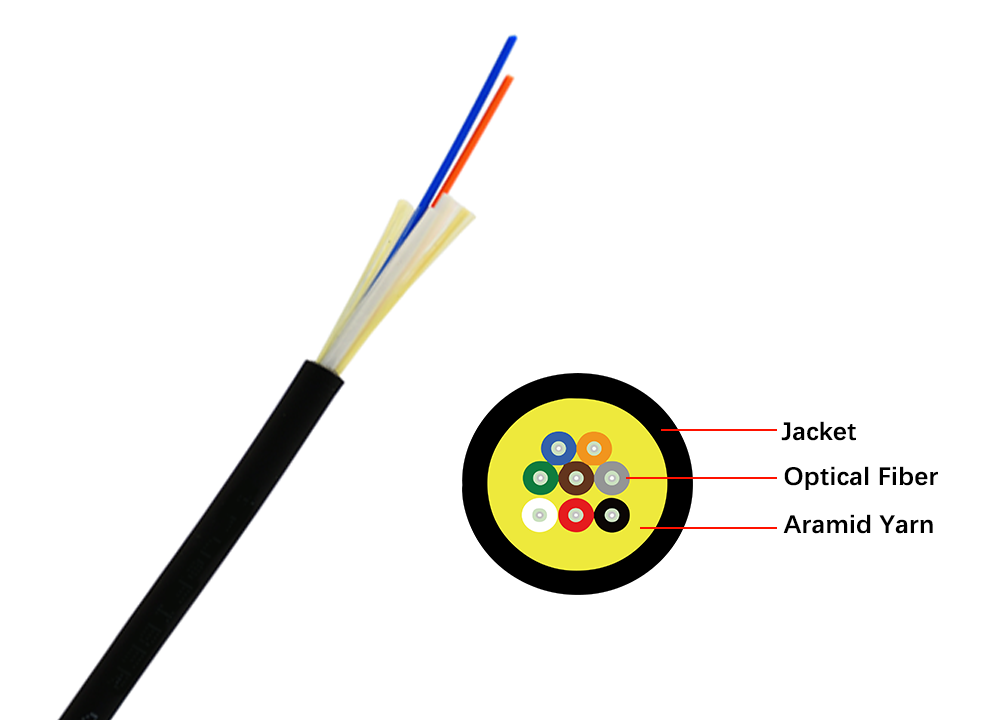

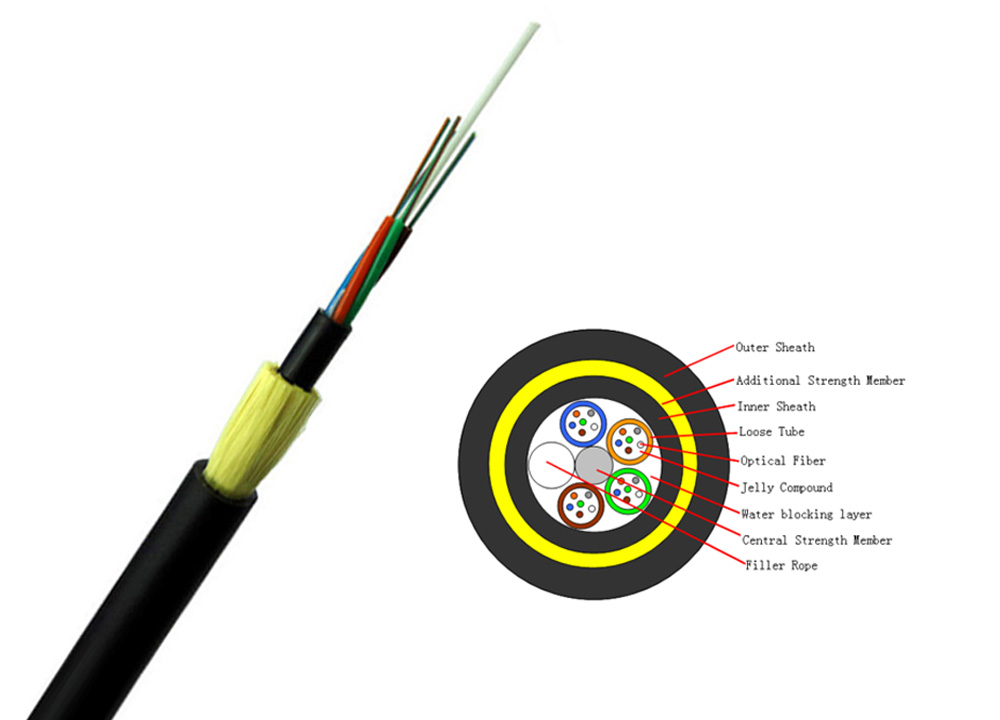

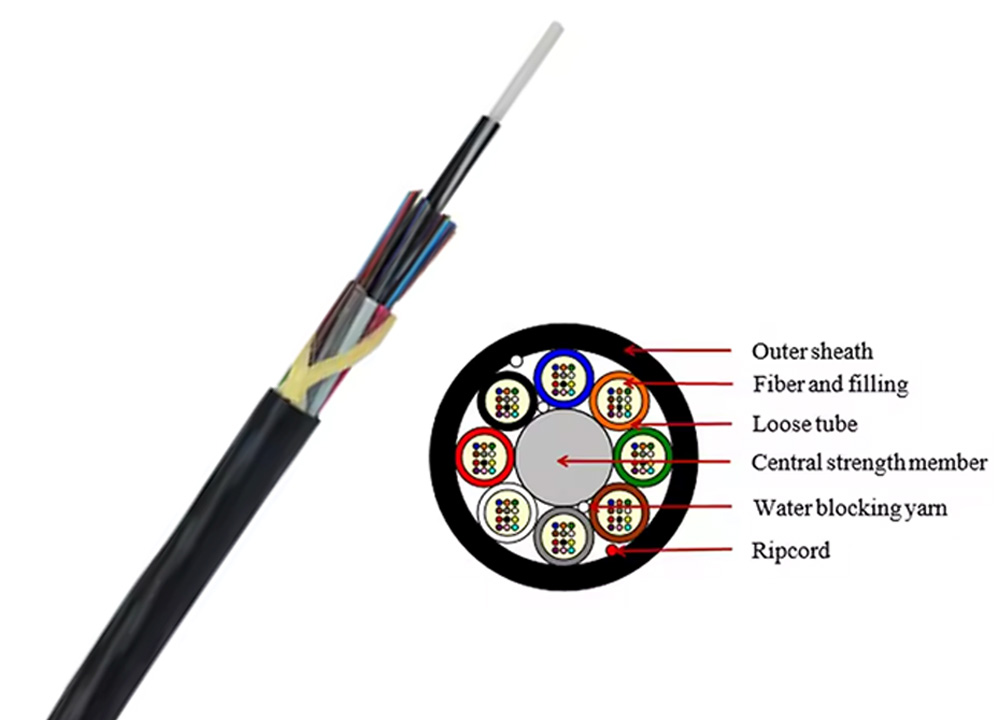

Fiber optics, or optical fibers, are long, thin strands of carefully drawn glass about the diameter of a human hair. These strands are arranged in bundles called optical cables. We rely on them to transmit light signals over long distances. Contact UnitekFiber, a professional fiber optic products supplier, for the fiber optic cable price.

Copper cables were originally designed for voice transmission and have limited bandwidth. Fiber optic cables provide more bandwidth for carrying more data than copper cables of the same diameter. Within the fiber cable family, singlemode fiber delivers up to twice the throughput of multimode fiber.

Fiber optic cables have a core that carries light to transmit data. This allows fiber optic cables to carry signals at speeds that are only about 31 percent slower than the speed of light—faster than Cat5 or Cat6 copper cables. There is also less signal degradation with fiber cables.

Fiber optic cables can carry signals much farther than the typical 328-foot limitation for copper cables. For example, some 10 Gbps singlemode fiber cables can carry signals almost 25 miles. The actual distance depends on the type of cable, the wavelength and the network.

Fiber optics is used for long-distance and high-performance data networking. It is also commonly used in telecommunication services, such as internet, television and telephones.

During the appointment, the technician will install a small utility box called an optical network terminal (or ONT) outside or inside your home. The tech will then run a cable from a nearby equipment box to the ONT, which will carry the fiber-optic connection from the larger network to your premises.

Currently, most ISPs offer fiber-optic speeds as fast as 1,000 Mbps. However, experts theorize that one strand of fiber-optic cable can transmit up to 44 Tbps. To put that into context, one terabyte is equal to 1 million megabits.