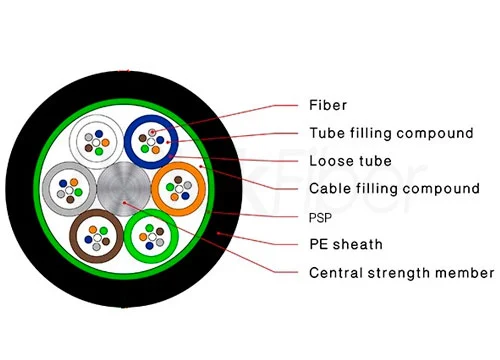

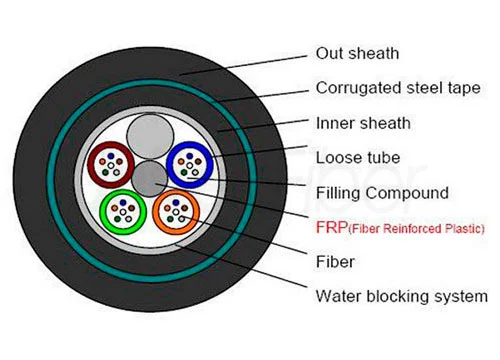

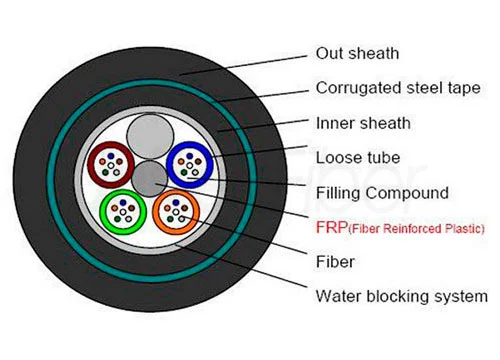

The GYFTY53 fiber cable is constructed by inserting a 250um fibers into a loose tube made of a high-modulus material filled with a water-resistant compound.

A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member.The tubes (and fillers) are stranded around the strength member into a compact and circular core. The fiber optic cable core is extruded with a polyethylene inner sheath,which is filled with jelly to protect it from water ingress. After a corrugated steel tape armor is applied. the cable is completed with a PE outer sheath.

lFull cross-section water-blocking structure to ensure good water blocking and moisture resistance.

lLoose tube is filled with special ointment for key protection of fiber.

lGlass yarn to ensure the the optical cable has good tensile properties, and rat-bite prevention.

lNon-metallic strength member is applicable for multi-thunder area.

lProduct life is 30 years.

lCore Network, Metropolitan Area Network, and Access Network Outdoor Optical Cable

lLaying method: Aerial, pipeline and direct buried

lWorking temperature: -40℃~+60℃

lBend radius: Static 12.5 times the cable diameter

lDynamic 25 times optical cable diameter

Yes, with qualified ISO9001, ROHS, UL raw material suppliers.

This duct fiber optical cable is usually in Stranded loose tube structure.

2-288cores.

The MOQ of duct fiber optic cable is 2km.

Yes, we supply OEM&ODM service, please feel free to contact us.

On time delivery and always has great customer service!