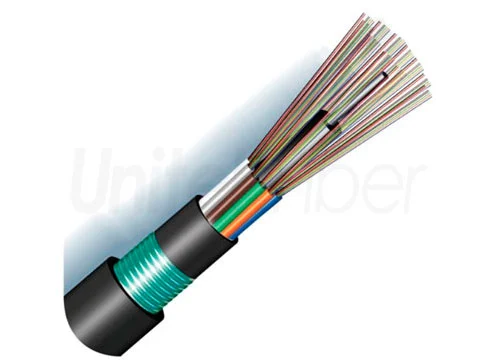

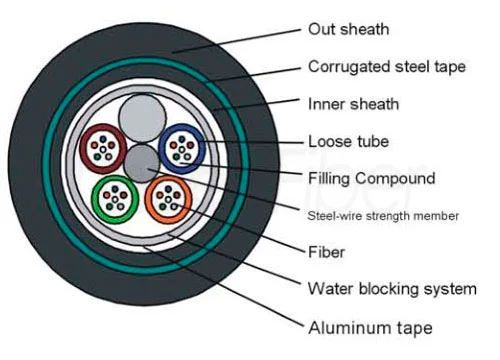

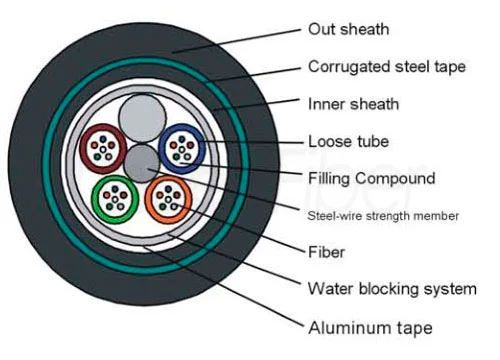

GYTA53 layer twisted double-twist double-sheathed fiber cable resists rat bites. The cable structure is that twisted 5 or 6pcs of loose tubes with waterproof fillings together. The center of the GYTA53 stranded double-twisted double-sheathed cable core is a metal reinforcing member.

For some cables, the metal reinforcing member needs to be extruded with a layer of polyethylene (PE). After the plastic coated aluminum strip (APL) is longitudinally wrapped, a polyethylene inner sheath is extruded, and the double-coated plastic strip (PSP) is longitudinally wrapped and extruded into a polyethylene sheath to form a fiber cable.

lFull section water blocking structure, double-coated aluminum tape longitudinal package, ensuring good water and moisture resistance

lLoose sleeve filled with special ointment for critical fiber protection

lPhosphating steel wire center strengthening member high modulus, corrosion resistance

lAdopt SZ twisted structure, easy to branch and ensure the optical fiber is not stressed under harsh environment

lLongitudinal double-sided coated steel tape armored, effectively improving the cable resistance to pressure measurement

lPolyethylene sheath makes the cable have good UV resistance

lProduct life more than 30 years

lCore Network, Metropolitan Area Network, and Access Network Outdoor Optical Cable

lLaying method:Buried directly, pipeline

lWorking temperature: -40℃~+60℃

lBend radius: Static 12.5 times the cable diameter

lDynamic 25 times optical cable diameter

The anti-rodent armored fiber optical cable is made of stainless steel as a protective structure, which protects the optical fiber very well.

Because mice have the habit of grinding their teeth, it is very destructive, and the broken optical cable causes the network to be paralyzed.

Add chemical components to the sheath, use multi-layer sheath armored.

Yes, can be overhead and pipeline application.

The MOQ of anti-rodent fiber optic cable is 2km.

I am extremely impressed with your products, fiber optic cable. My father would have loved buying these products from your company.