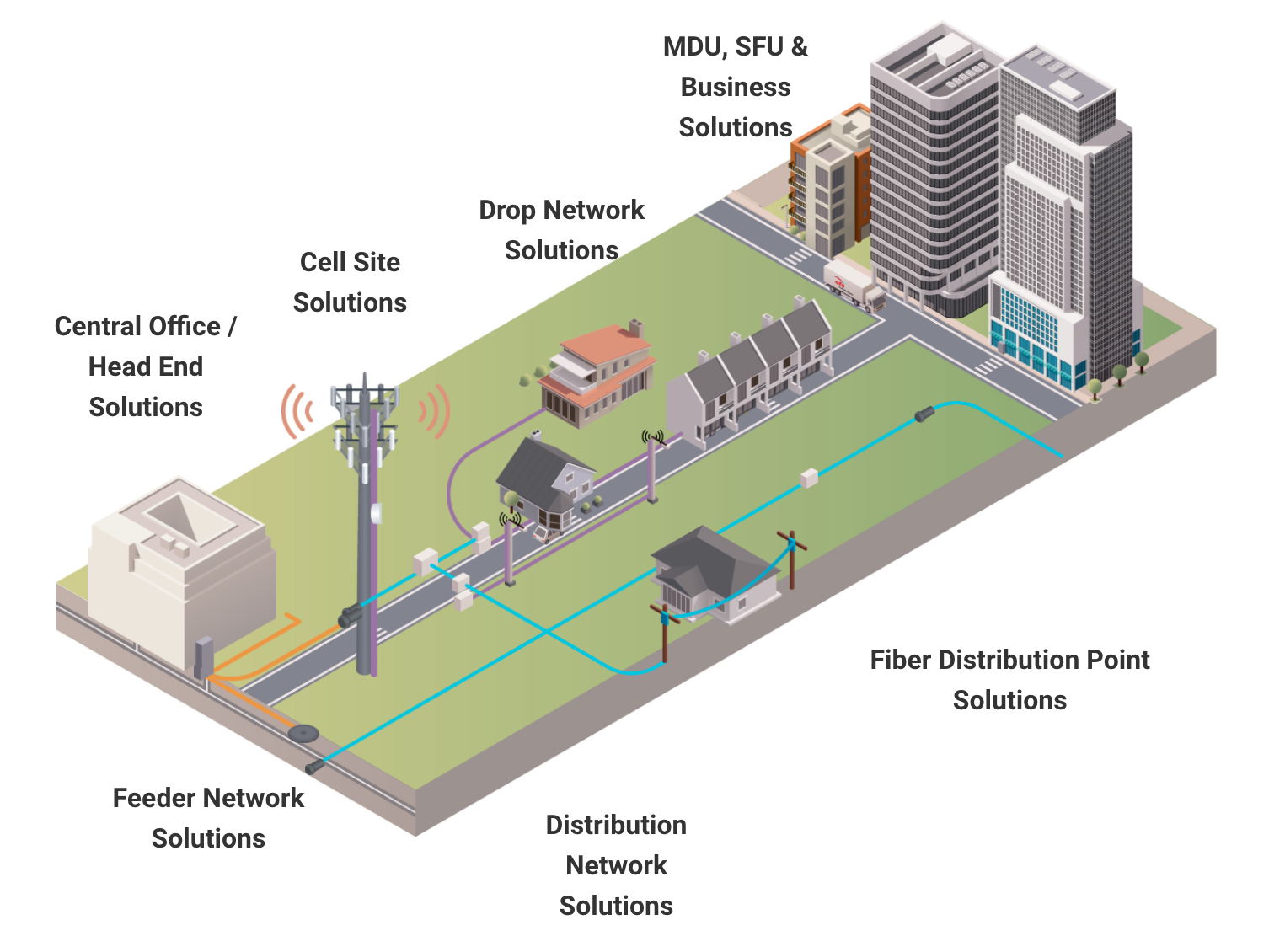

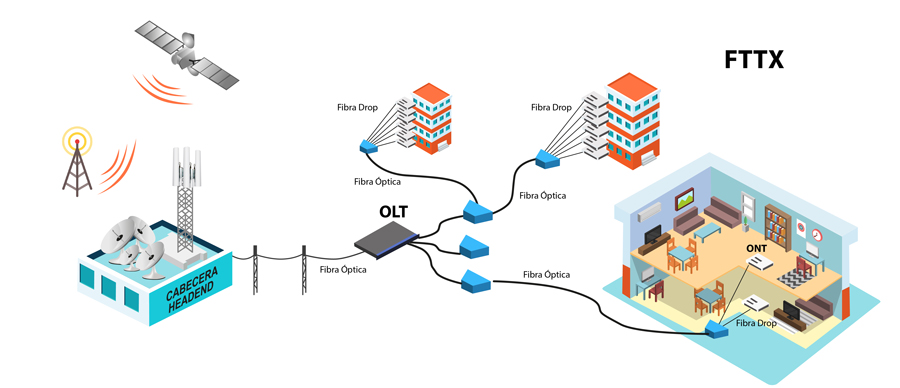

Fiber optic drop cable is a key component of any broadband network. The fiber drop cable connects the side of a house or multi-family building to the fiber optic distribution box where the fiber drop cable is connected. Fiber optic drop cable can be installed overhead on utility poles or cable lines, underground in handholes, or installed overhead in nearby pedestals. Fiber optic drop cable are considered essential for the "last mile" of broadband connectivity.

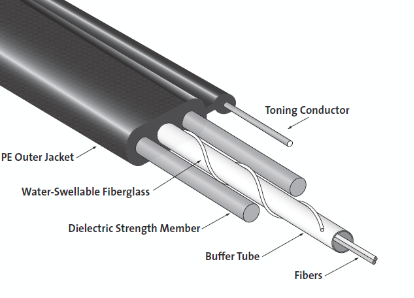

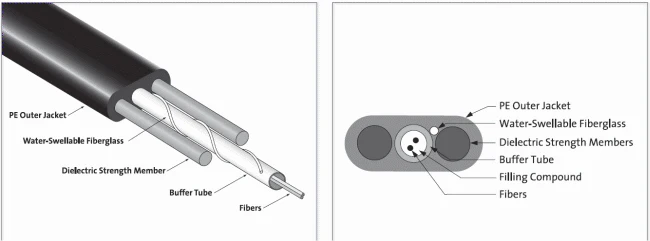

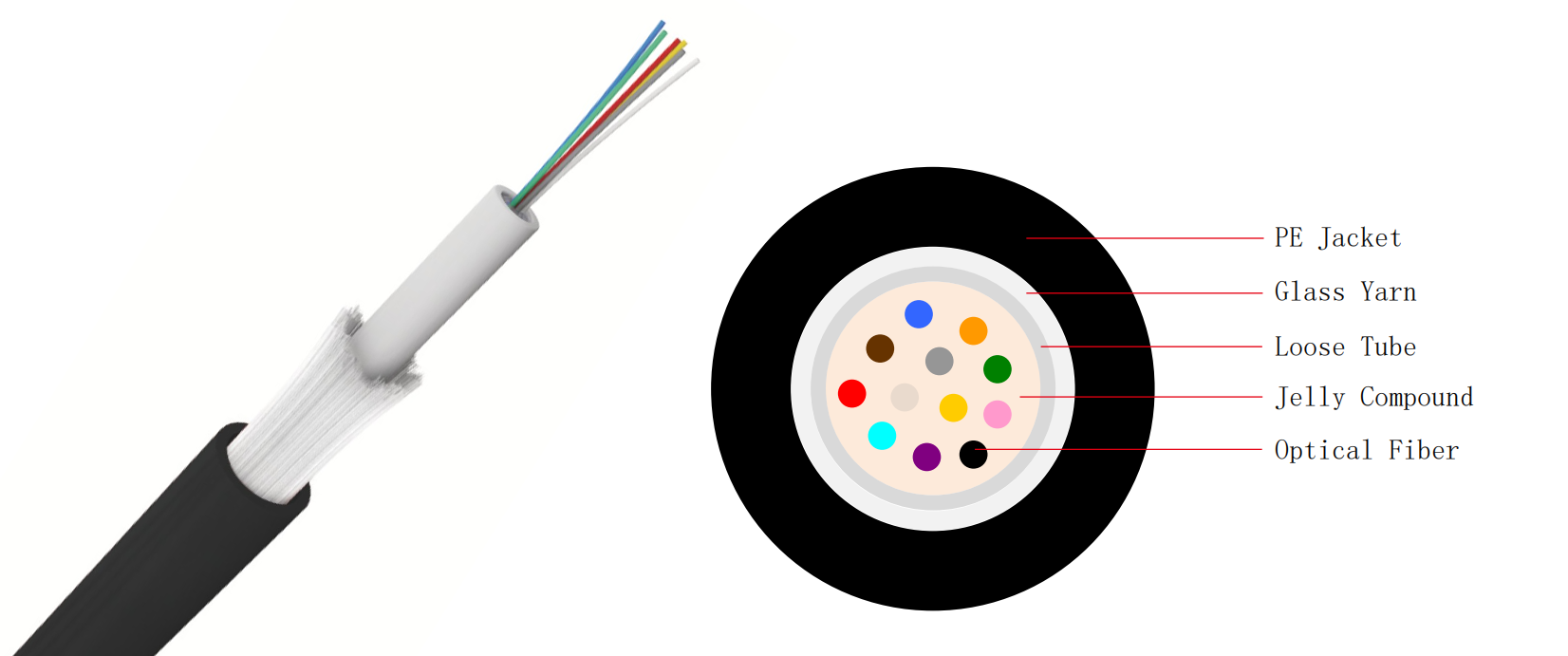

Fiber drop cable consist of one or more optical fibers encased in a protective layer consisting of a buffer tube or loose tube, strength members, and an outer jacket. The buffer tube of drop cable surrounds the individual fibers, while glass fiber or steel strength members provide rigidity and protection, and the outer jacket protects the entire cable. If properly planned and installed, fiber optic drop cables should be able to withstand most environmental factors.

There are different types of fiber optic drop cables, which could be customized with specific installation requirements, such as aerial or underground deployment. The key advantages of fiber optic drop cables include high data rates and resistance to electromagnetic interference, making them an ideal choice for modern broadband and telecommunications networks. Both types of drop cables have their uses in different installation configurations.

With an ideal condition, fiber optic drop cables are expected to last for years. Fiber optic drop cables are tested according to industry standards to ensure they can withstand the elements. As part of quality control, the fiber drop cables are tested for tensile strength, repeated flexing, impact resistance, torsion resistance, compressive strength, and resistance to temperature fluctuations according to specific standards. Because the fiber drop cables are subjected to these forces every day, these tests help ensure that the drop cables maintain their integrity in real world applications.

Fiber optic drop cables come in a variety of different configurations. Different configurations offer varying degrees of protection and flexibility, impacting overall cost, such as flat drop cables, round drop cables, figure-eight drop cables, and armored drop cables.

Toneable drop cable contain a metal element that runs parallel to the optical fiber. This element, typically made of copper or steel wire, allows the drop cable to be traced or located using a metal detector or tone generator. This makes tunable drop cables ideal for buried applications.

Nontoneable drop cable does not contain contain metallic tracing wires, making them more flexible. Nontoneable drop cable are typically used in aerial applications.

Tight-buffered fiber drop cables are a common choice when installing mechanical connectors into fiber optic terminal box. Fiber optic terminal box is a small, weatherproof enclosures, typically made of plastic, that house terminations from the main network to the residence. Many installers recommend choosing 900um and stripping it down to the bare fiber for termination because there is known to be less retraction than when loose tube fiber drop cable on long span lengths.

Loose-tube fiber drop cable contains a 250um optical fiber wrapped in a thick layer of gel or treated aramid yarn to prevent water penetration. When installers are splicing on the side of a house or in a fiber optic terminal box, loose-tube fiber drop cable is preferred because it is smaller and easier to store.

ion

ionLoose-tube and tight-buffered fiber drop cable utilize similar fiber assemblies, however, they are suited for different applications and environments. Tight buffered fiber drop cable utilizes a hard plastic jacket for enhanced protection and is suitable for environments where physical protection is crucial. Loose tube fiber drop cable features a flexible jacket and waterproofing options, making it ideal for installations requiring greater versatility and reduced installation time.

Network planners can design efficient systems that meet performance requirements without incurring unnecessary costs by understanding the performance and limitations of each fiber optic drop cable type and the impact of environmental factors on service life.

UnitekFiber is a perfessional factory that producing high quality fiber optic drop cable. Please contact us via sales@unitekfiber.com for competible pricing.

+86-755-21034367