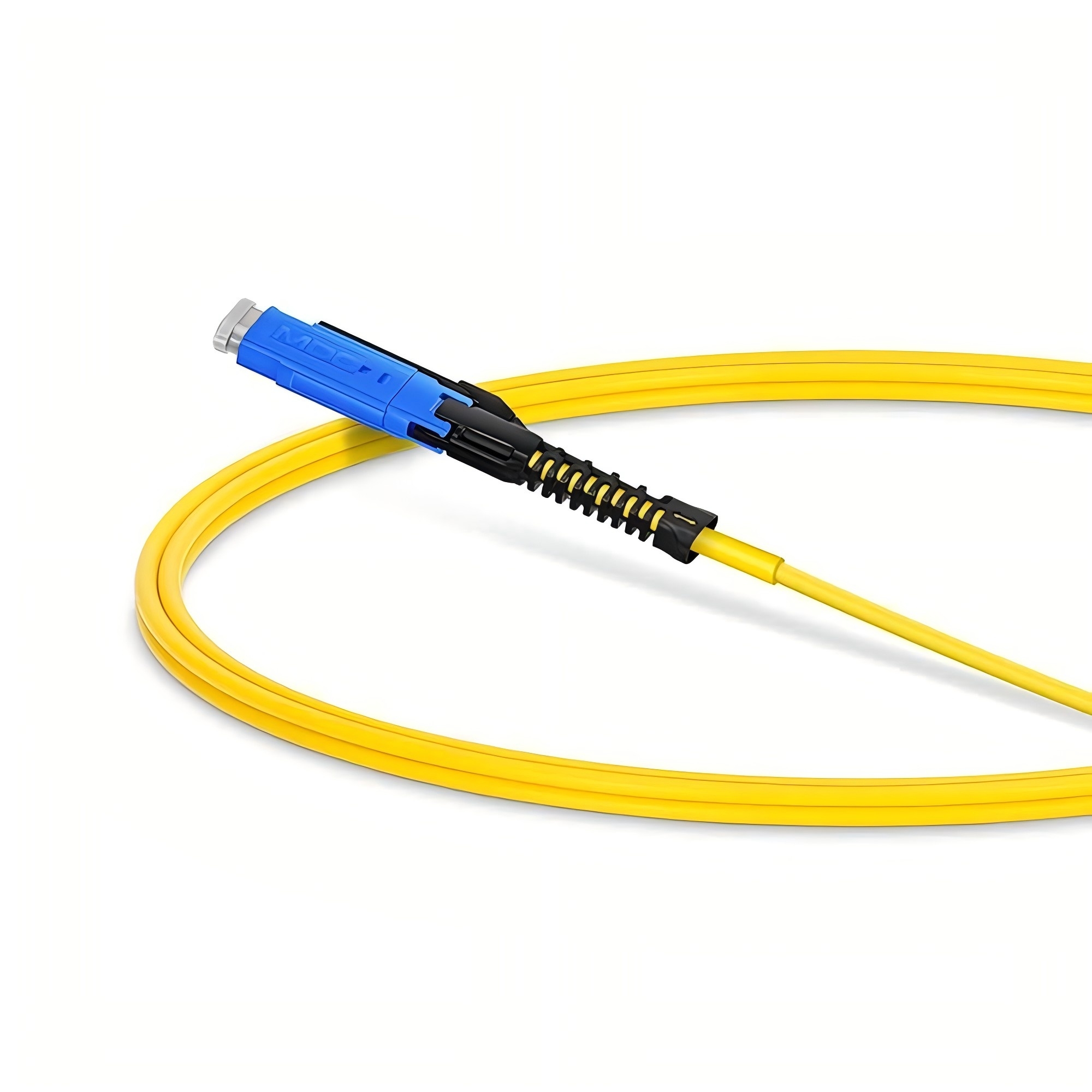

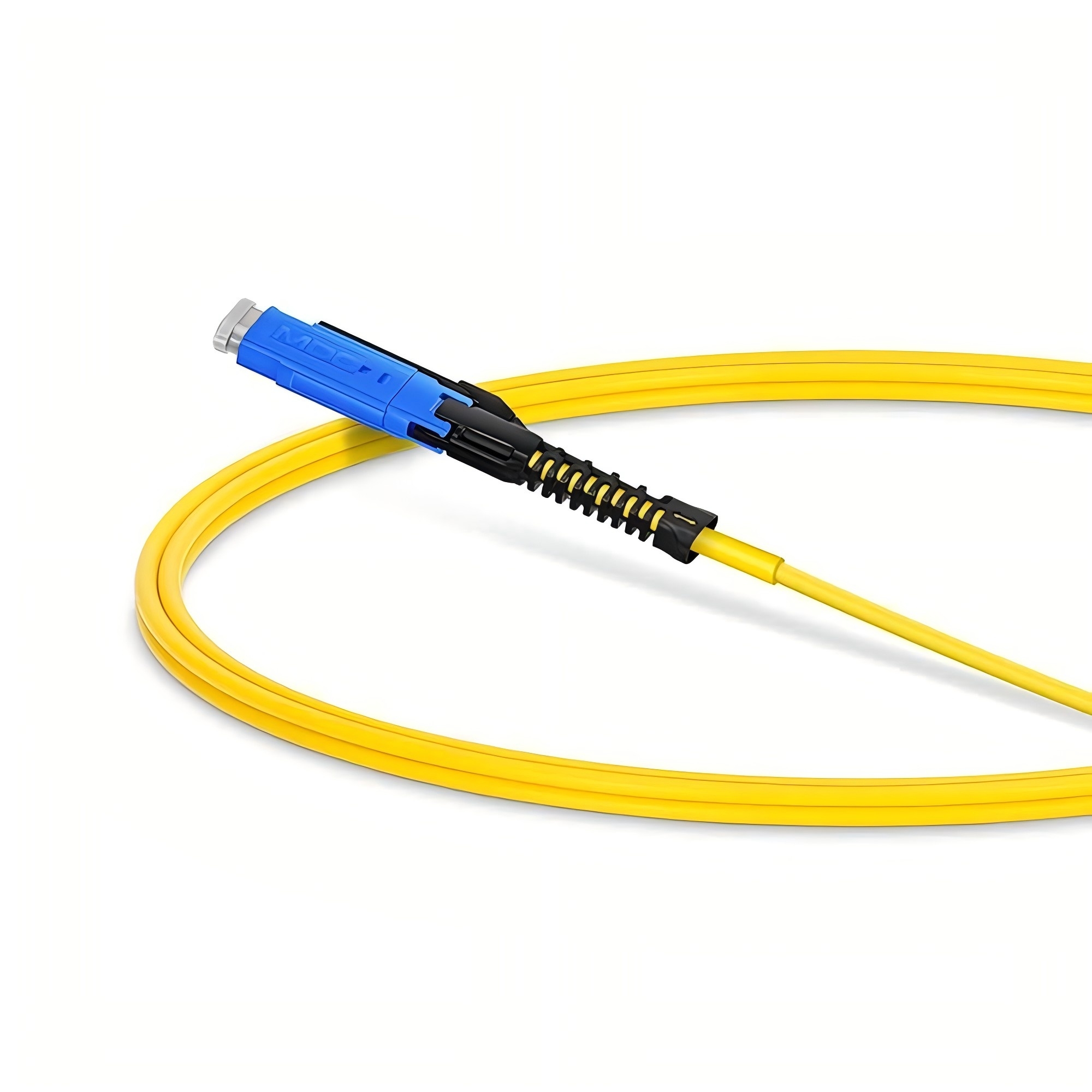

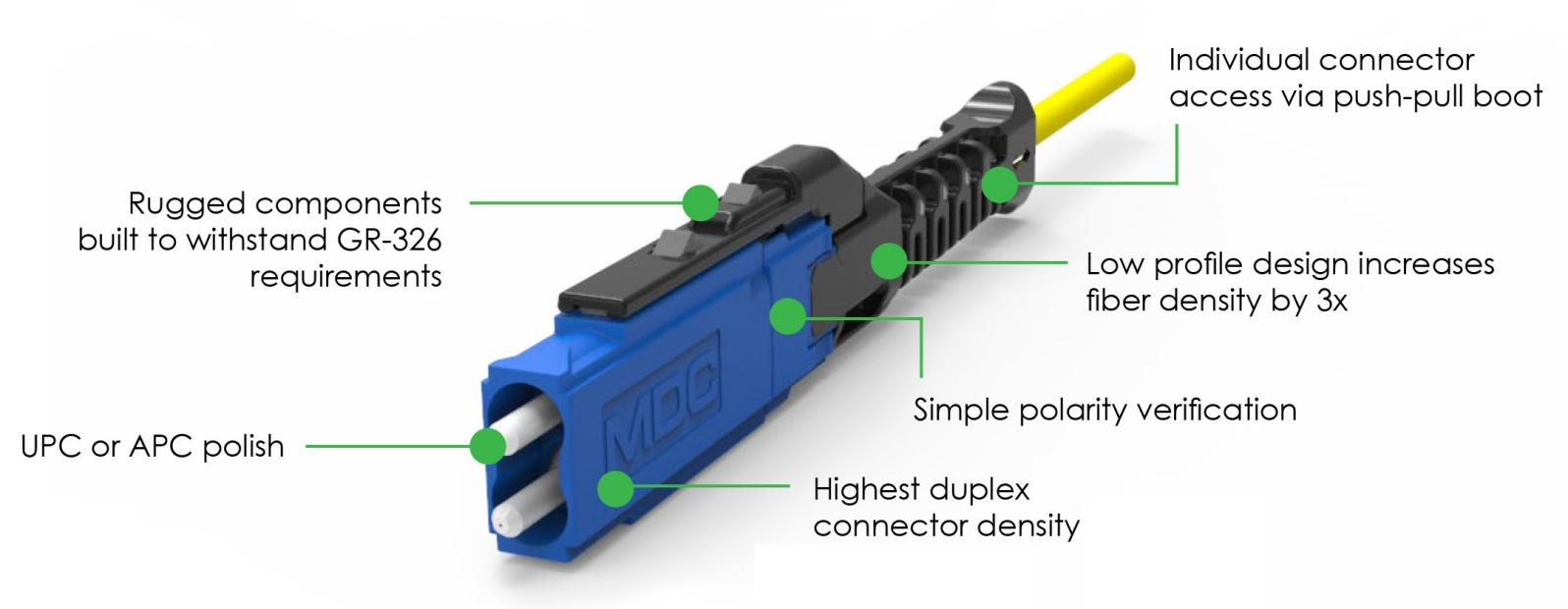

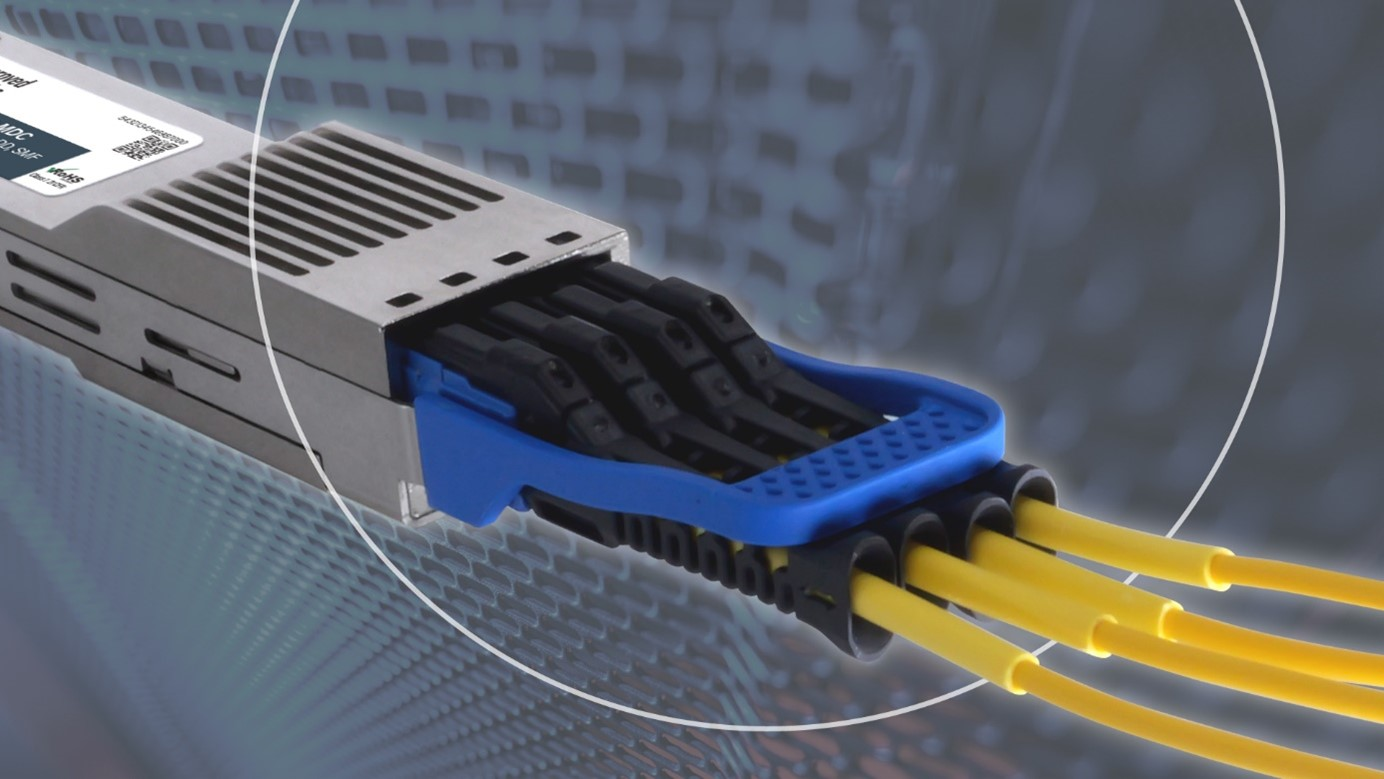

Equipped with the MDC connector, a VSFF duplex optical connector, the MDC fiber patch cord adopts reliable 1.25mm LC ferrules and is engineered to terminate 2.0mm micro cables. The uniboot design allows one cable to carry two fibers to reduce cable. MDC fiber patch cord enables to achieve three times the density compared to LC fiber patch cords. By using the revolutionary push-pull strain relief boot, the MDC fiber patch cord could easily access in the most extremely dense connector environments. The polarity reversal of the MDC connector allows for quick and easy polarity conversion without exposing the fibers or needing any tools. The MDC fiber patch cord was designed for breakout application in QSFP-DD, SFP-DD, and OSFP optical transceivers, as well as to challenge the current situation for patch panel density.

Engineered for high density network deployments, the MDC fiber patch cord is constructed with rugged components that meet GR-326 requirements, ensuring long term stable performance during extended operational use. Featuring the DirectConec™ push-pull boot, the MDC fiber patch cord enables effortless individual connector access. The unique feature of MDC fiber patch cord is its low profile design, which boosts fiber density by 3x compared to LC fiber patch cord solutions. For seamless network deployment, the MDC fiber patch cord integrates simple polarity reversal, eliminating costly configuration errors and accelerating system commissioning. In addition, the singlemode MDC fiber patch cord is available with both APC and UPC polish type, catering to diverse application needs, from high loss sensitive FTTx networks to high speed data center links.

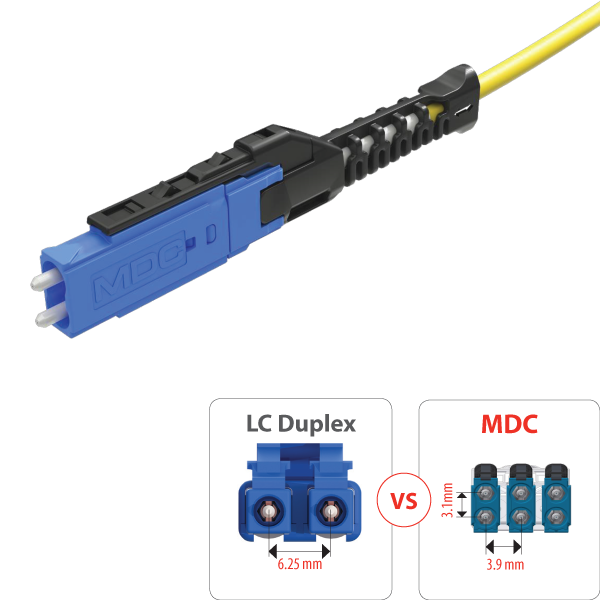

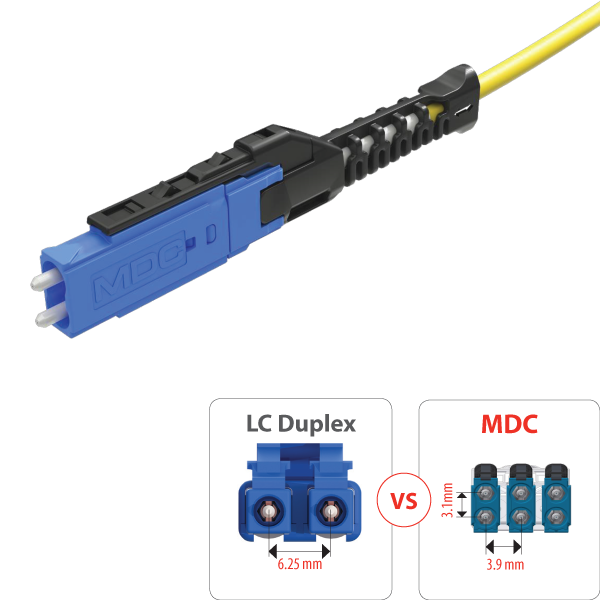

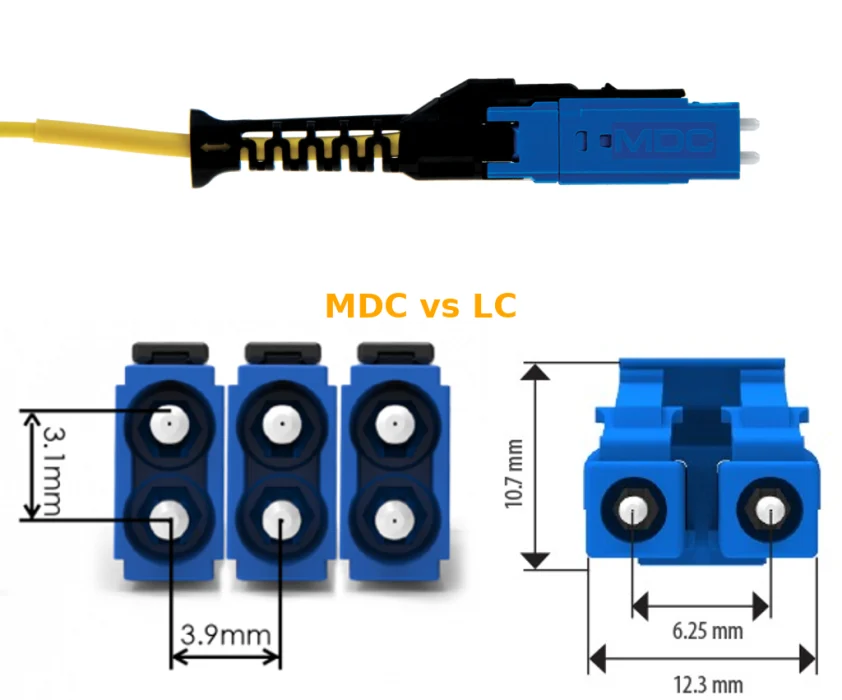

MDC fiber patch cord features a very small form factor (VSFF) design, enabling direct installation into standard duplex LC adapter panels via duplex or three-port MDC fiber adapters. MDC fiber patch cord can increase cabling density up to three times compared to LC connectors. For instance, a 1U high density fiber patch panel can accommodate 216 MDC connectors (equivalent to 432 cores). Thus, the MDC fiber patch cord significantly reduces cabinet or fiber optic patch panel space requirements in high density cabling environments. Meanwhile, the 2.0 mm uniboot fiber cable design allows one cable to carry two fibers. This design not only streamlines cable management but also minimizes wiring clutter, ensuring a neat and organized cabling layout.

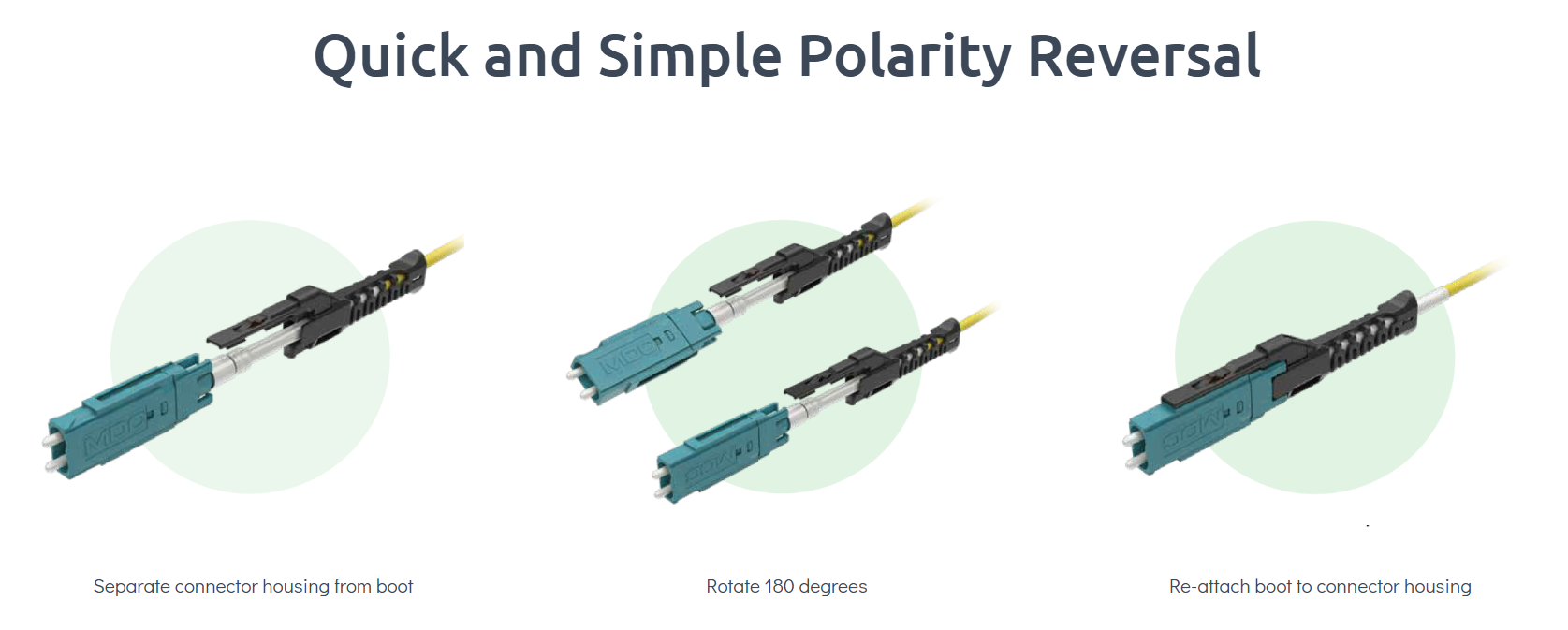

Utilizing push-pull strain relief boot design, the connectors of MDC patchcord can be easily plugged in and unplugged without tools, allowing for precise operation of individual interfaces even in densely packed environments. MDC fiber patchcord also supports quick polarity reversal in data center, just simply remove the protective boot from the MDC connector housing, rotate it 180 degrees, and then reattach the boot to the connector housing. The fiber is not exposed or twisted during this process, significantly reducing maintenance downtime.

MDC fiber patch cord is purpose built to address the most demanding connectivity challenges across a spectrum of high density, high bandwidth optical network scenarios. Such as high density cabling systems in ultra large data centers and cloud computing centers, 200G/400G/800G high speed Ethernet and optical module branch connections, space optimization and upgrade projects for enterprise data centers and carrier backbone networks, interconnection scenarios between QSFP-DD/SFP-DD/OSFP optical modules and patch panels, edge computing nodes with high demands on cabling density and maintenance efficiency or ect.

Yes, DirectConec™ means push pull boot, it's a trademark of US Conec. The design allows you to easily insert and extract in extremely dense applications without affecting the neighboring connectors.

MDC fiber patchcord differs from standard duplex LC patchcord by featuring smaller, more compact connectors that enable higher port density on patch panels and equipment.

Yes, we offer all kind of singlemode and multimode fiber option, please kindly contact us for more details.

Common jacket materials include: LSZH, PVC, PVC-OFNR, PVC-OFNP

As a perfessional fiber optic manufacture, we offer custom lengths to meet specific installation needs for customized length.

As a data center procurement manager, we needed high density MDC cable to maximize rack space. Their compact connectors let us 3x port density on patch panels, and the low insertion loss (dB) ensures stable 100G transmission. Highly recommend!

We ordered customized 8m MDC fiber patch cord for our office building vertical runs, and the LSZH jacket was a great.

Purchased singlemode MDC cable support 40G transmission without signal degradation, and the bend insensitive G657A1 fiber design meant we didn’t have to reroute around tight corners. Meets Telcordia standards, so quality is reliable for using.

We switched to MDC patchcord for our 400G data center upgrade, and the difference is night and day. And it reduces cable clutter by 60%, and it shipped fast, which met our tight project timeline.

We bought OM4 multi-mode MDC jumpers for short-reach (150m) 100G links, and the transmission speed is consistent. Great product.