Between the towers of high-voltage transmission lines, these cables seemingly ordinary fiber optical cables are silently carrying the transmission of power. These fiber optical cables, which do not require metal supports and are directly suspended, are called ADSS (All-Dielectric Self-Supported Optical Cable) and are overhead optical cables specifically designed for power communication.

Depending on the application, ADSS cables are divided into two structures:

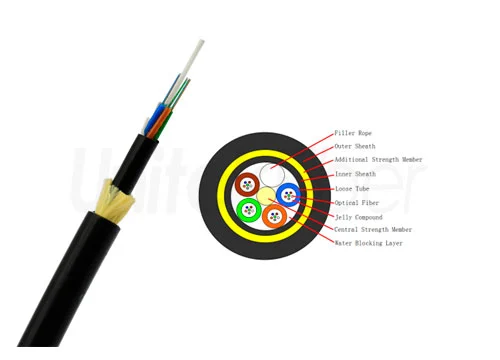

Stranded Loose tube: Multiple loose tubes of optical fibers are spirally twisted around a central strengthening member, with an outer layer of aramid yarn and a sheath. This design offers better control over fiber excess length and stable mechanical performance, making it suitable for long-span, high-tension applications (such as UHV transmission lines).

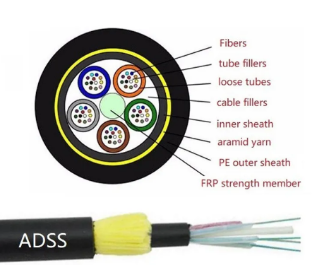

Center Loose tube: The loose tube of optical fiber is located at the center of the cable, surrounded by high-strength aramid yarn, with an outer extruded sheath. It has a smaller diameter, lighter weight, and lower icing/wind load, making it suitable for applications with shorter spans and weight sensitivity (such as urban power distribution networks).

Fiber Optic ADSS Cable stands for "All-Dielectric Self-Supporting Optical Fiber Cable," meaning a non-metallic, self-supporting fiber optical cable. Its core advantages lie in its "all-dielectric" and "self-supporting" properties:

All-Metallic Insulation Design: The ADSS cable contains no metal components. It uses non-metallic materials such as aramid yarn and fiberglass reinforced plastic (FRP) as the reinforcing core, and is wrapped with a polyethylene (PE) or anti-tracking (AT) sheath. This design provides complete insulation in high-voltage electric fields, avoiding induced current and lightning strike risks, making it far safer than traditional metallic optical cables.

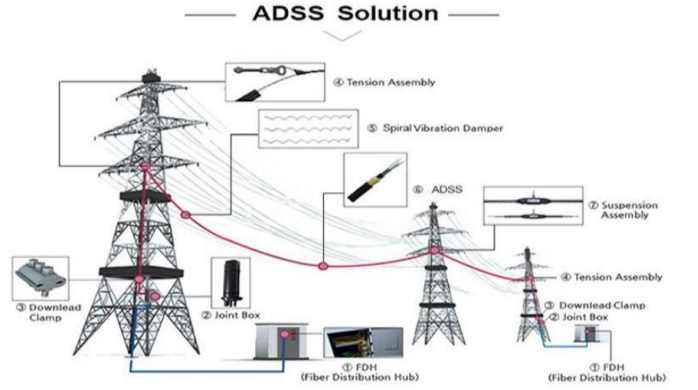

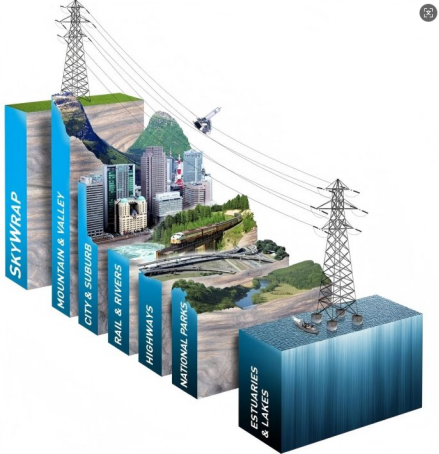

Self-Supporting Capability: Without the needs of additional steel cables, ducts, and towers, ADSS cables can be directly suspended from power transmission towers, streetlight poles, and other facilities, relying on their own structure to withstand tension, wind, and ice loads. Its maximum span can reach 800 meters, and it can even cross rivers, valleys, and other complex terrains.

The advent of Fiber optical ADSS cables has fundamentally changed the construction model of power communication:

High-voltage transmission line communication: In 110kV-500kV transmission lines, ADSS optical cables can be directly attached to the towers to realize communication functions such as dispatch automation, relay protection, and real-time monitoring. For example, in the State Grid's ultra-high-voltage projects, ADSS optical cables are used in conjunction with OPGW (optical fiber composite overhead ground wire) to construct a dual-circuit power-communication system.

Existing network upgrades and rapid deployment: In urban and rural power grid upgrades, ADSS fiber cables do not require the construction of new towers. They can quickly achieve fiber optic coverage using existing power channels. ADSS optical cables have been used in the construction of 5G base stations to achieve "fiber to the tower," significantly shortening the construction cycle.

Cross-obstacle communication: Cross-obstacle communication using fiber optic ADSS (All-Dielectric Self-Supporting) cable involves deploying these lightweight, non-metallic fiber optic cables across spans like rivers, roads, and valleys, leveraging their self-supporting design and immunity to electromagnetic interference (EMI) for reliable communication where traditional poles are difficult, allowing quick installation along power lines or as standalone routes for high-speed data, with specific hardware like protective sleeves and warning signs used at crossings for safety.

Despite the strong adaptability of ADSS optical cables, construction and selection still require strict adherence to specifications:

Sheath Selection: Select sheath material based on spatial potential—PE sheath for lines with a field strength ≤12kV, and AT sheath for lines with a field strength ≤25kV.

Tension Control: Precise calculation of sag and tension is necessary during construction to prevent performance degradation due to excessive stretching or slack.

Environmental Adaptability: In areas with frequent lightning strikes and high corrosion, lightning-resistant and corrosion-resistant optical cables must be selected; under extreme temperature conditions, their temperature adaptability must be verified.

ADSS cables, with their "all-dielectric, self-supporting" characteristics, have become a "hidden champion" in the power communication field. They not only reduce construction costs but also improve the reliability and coverage of communication networks. In the future, with the deep integration of smart grids and 5G technology, ADSS optical cables will continue to play a decisive role in power communication projects.As a professional fiber optic cables manufacturer,Unitek Fiber provide types of fiber optic cables,such as Anti-rodent fiber optic cables,ADSS fiber optic cables,Figure 8 fiber cables and underground fiber optic cables.If you have question or need,please don’t hesitate to contact us at sales@unitekfiber.com,we will try our best to support you.