Outdoor special fiber optic cables, due to their unique performance characteristics, are widely used in applications where specific requirements for fiber optic cables exist. Below are some typical application scenarios and the corresponding types of outdoor special fiber cables:

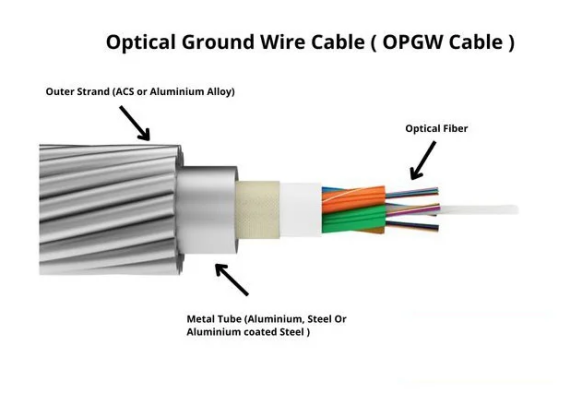

OPGW (Optical Ground Wire): Combining lightning protection and communication functions, it is suitable for newly constructed high-voltage transmission lines of 66kV and above. Its metal armored outer layer can withstand high-voltage electrical corrosion and meets the requirements for long spans, making it a core component of power communication networks.

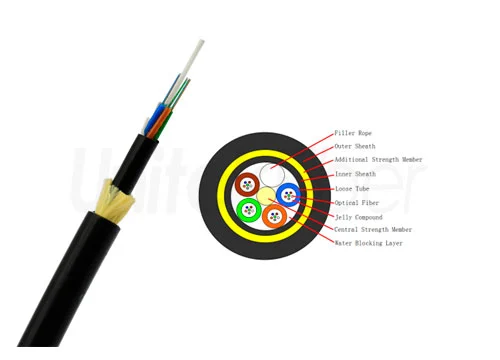

ADSS (All-Dielectric Self-Supporting Fiber Optical Cable): Utilizes a non-metallic structure, supports live-line installation, and is suitable for upgrading existing networks or in areas with severe electrochemical corrosion. It has high tensile strength and can span large distances across rivers, valleys, and other challenging terrains.

OPLC (Optical Fiber Composite Low-Voltage Cable): Integrates optical fibers and power lines, supporting broadband access, power supply for equipment, and emergency signal transmission. It is suitable for applications such as smart communities and electric vehicle charging stations, enabling functions like remote power meter reading and interactive power consumption management.

OPPC (Optical Phase Conductor): This technology integrates optical fibers into the power transmission phase conductor, suitable for agricultural power grids or rural distribution networks, addressing issues such as simplified fiber optical cable branching and severe electrochemical corrosion.

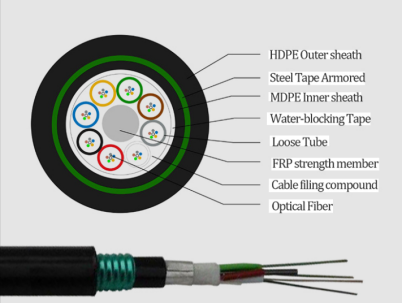

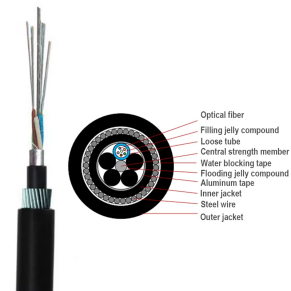

Rodent-resistant fiber optical cable (GYTA53 stainless steel tape): The armored layer uses stainless steel tape, providing resistance to gnawing and corrosion. It is suitable for areas with high rodent activity, such as farmland and forests, and can be installed overhead, in conduits, or directly buried.

Reinforced direct-buried fiber optic cable (GYTA33): Single-layer steel wire armored, with strong tensile and lateral pressure resistance, suitable for direct burial applications in mountainous and hilly areas where high tensile strength is required.

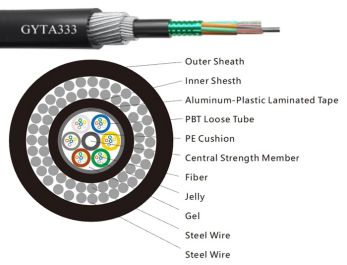

Underwater fiber optic cable (GYTA333): Features double-layer steel wire armor, providing excellent tensile strength and lateral pressure resistance. It is suitable for unstable riverbeds, high-flow rivers, or navigable waterways. Available in different tensile strength ratings, including 4T and above, to suit various underwater environments.

High-temperature resistant fiber optic cables: Used in high-temperature environments such as petrochemical plants and converter valves, ensuring stable signal transmission.

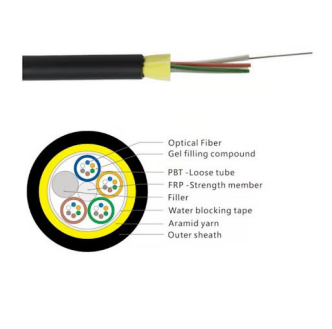

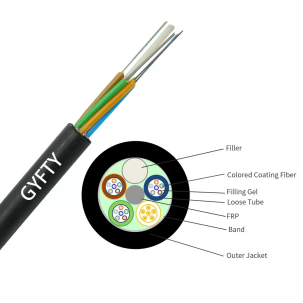

Non-metal fiber optic cables (such as GYFTY): Contain no metal components, are resistant to electromagnetic interference, and are suitable for high-voltage areas, areas prone to lightning strikes, or chemically corrosive environments.

Lightweight all-dielectric figure-8 cable (GYFXTC8F): Non-metallic structure, suitable for self-supporting aerial installation with spans of up to 50 meters (maximum 100 meters), and can be attached to 10kV power poles. It is suitable for urban slum areas, rural residential areas, and similar scenarios.

ADSS fiber cable: Supports long-span aerial installation and is suitable for use under power lines or for crossing obstacles.

Stranded Air-blown Micro-cable Outdoor Fiber Optic Cable(GYCFY):With a small outer diameter, it can be installed in microducts using an air-blowing method, achieving a single-pass blowing distance of up to 1 km. This makes it suitable for applications requiring a large number of fiber optic cores, such as trunk lines and metropolitan area network backbones.

Fiber optic sensing cables: Used in fields such as smart manufacturing and intelligent transportation, enabling real-time monitoring of parameters such as temperature, pressure, and vibration.

Vibration-sensing fiber optic cables: Laid along long-distance oil pipelines to detect leaks or acts of sabotage.

FOG polarization-maintaining fiber optic cable: Used in fiber optic gyroscopes, meeting the high-precision requirements of core components in aerospace applications.

Radiation-resistant fiber optical cable: Suitable for nuclear environments or space missions, ensuring signal transmission is unaffected by radiation interference.

Smart Community Construction: Using OPLC optic cables to achieve fiber-to-the-home (FTTH) with power supply, reducing wiring costs.

Oil Pipeline Monitoring: Deploying high-temperature resistant and tensile-strength fiber optic sensing cables to monitor pipeline status in real time and prevent leakage accidents.

Submarine Communication: Using underwater fiber optical cables (GYTA333) to ensure the stability and reliability of submarine optical communication.

Different application require different special types of fiber optic cables, Please contact us at Email sales@unitekfiber.com, if you have any inquiry or need any need.

+86-755-21034367