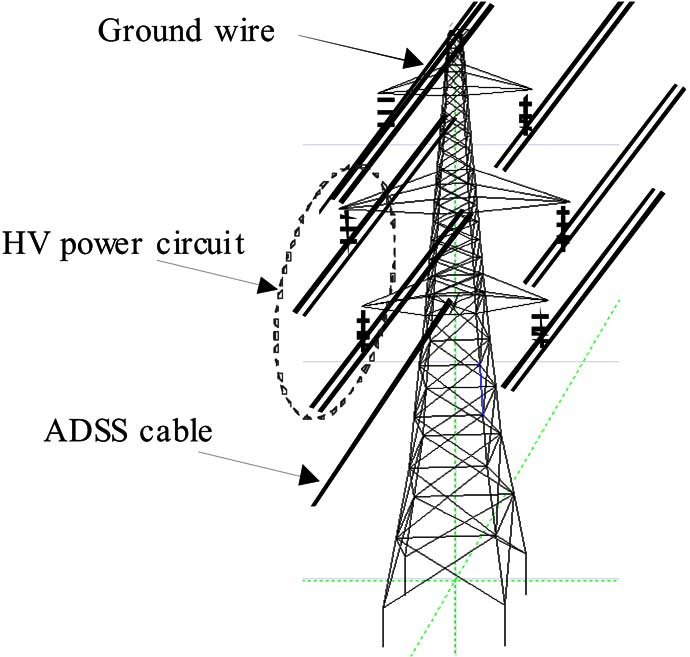

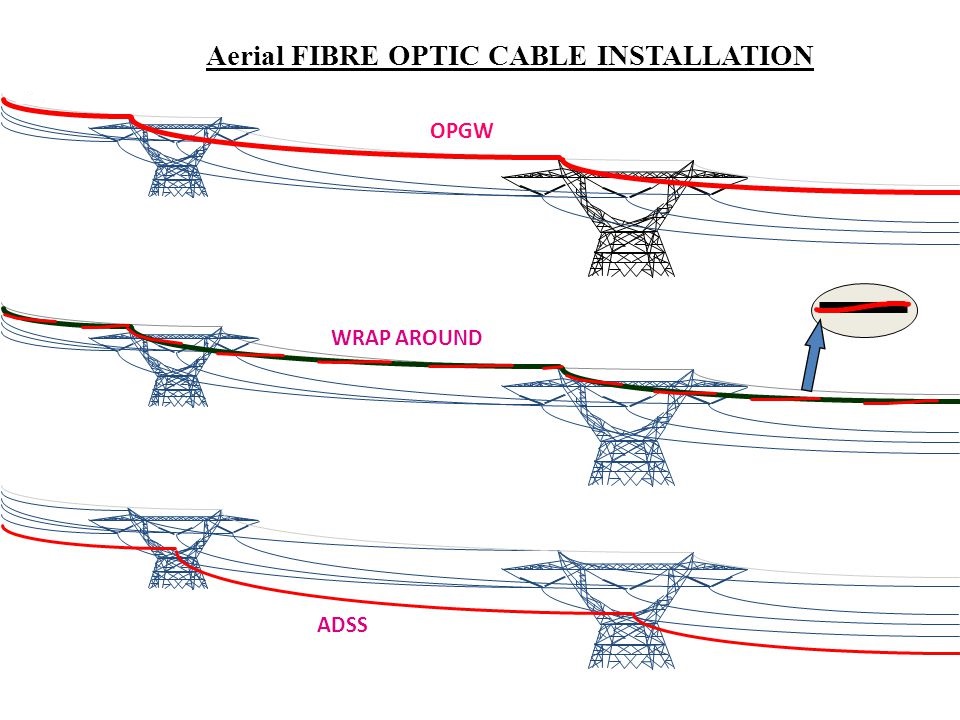

All-dielectric Self-supporting Optic Cable, referred to as ADSS cable. ADSS fiber optic cables are widely used on 220kV, 110kV, and 35kV voltage level transmission lines and existing lines. All-dielectric, that is, the optic cable uses all-dielectric materials, and the self-supporting type means that the optical cable itself can withstand its own weight and external load.

The Characteristics of ADSS Cable

ADSS cable is of lightweight, small cable diameter, small load to the tower, and is hang on the inside of the cable and can be erected without power cut. It adopts imported aramid yarn with good tensile performance and temperature performance, so that it can adapt to bad weather.

The ADSS cable has a long laying span and can reach up to 1200 meters.It is a self-supporting aerial optic cable with a fully insulating medium, which makes it prevent lightning strikes.

Besides, ADSS cable adopts polyethylene sheath, which has good electric corrosion resistance. In addition, what makes ADSS cable more reliable is that its service life can reach 30 years.

How to Prevent the Common Damage of ADSS Fiber Optic Cable?

What is external Damage of ADSS Fiber Optic Cable?

Because some fiber optic cable lines pass through hills or mountains, where there are rocky rocks and thorny grasses, the fiber cables are easily rubbed on the trees or rocks, and they are easily scratched or bent. Especially the cable sheath is wore and not smooth, it’s prone to occur electric corrosion in use because of the dust and inflammatory environments, which may cause great harm to the service life. There must be more than one person to supervise the construction, and the preparation work must be carefully checked before towing.

The Damage of Fiber Broken and High Loss Point

The phenomena of fiber breakage and high loss points are caused by local forces during the construction and laying-out process. During the laying of the ADSS optical cable, the cable wheel, the uneven speed and force, the diameter of the corner guide wheel, and the looping of the optical cable will all cause such consequences. Sometimes it is found that the center FRP is broken. Since the center FRP is a non-metallic material, the fiber optic cable retracts after being stretched, and the disconnection will be misaligned. The broken FRP will damage the loose tube of the fiber and even the fiber, which may cause high loss points. In more serious cases, fiber will break. This phenomenon is also a common failure. Many people think that it is a quality problem of the ADSS fiber optic cable, however, it’s actually caused by an accident during construction. Therefore, constant tension control during construction is very important, and it must be uniform.

The Damage of Fiber Broken Failure at Tensile End

The fiber breakage at the tensile end is also one of the frequent accidents. It often happens near the tensile hardware (pre-twisted wire), within 1 meter from the end of the hardware. Besides, the fiber breakage of the tensile end also occurs at parts drawn from the tower behind the hardware. The former is often caused by improper operation when pre-twisting the wire fittings, and the latter is usually caused by too small towing end angle when tighten wire , which due to the inconvenient terrain. In addition to this, the latter phenomenon can also caused by the local force of ADSS cable, which resulted from short-time extremely small bending radius of force with the tower(pole). During construction process, the traction direction should be consistent with the direction of the optical cable, so that the optical cable is subjected to a straight line.

Since both the ADSS optic cable sheath material and the force-receiving element are all of good elastic properties, there usually will be no obvious scars on the surface of the sheath after the ADSS fiber cable is subjected to a short period of force. However, the fiber optic components inside have been damaged by force. At this time, most people may think the quality of the ADSS fiber optic cable is defective, which will cause wrong judgement of the phenomenon.

According to the characteristics of the ADSS optic cable and the located line of ADSS cable, a certain number of spare cables, spare fittings, fiber splice closures and accessory materials should be equipped for emergency repair of the line. Corresponding instruments and special tools such as OTDR, fusion splicer, cutting knife, optical power meter, optical fiber stripper should also be equipped. What’s more, The line maintenance and operation management of ADSS cable should be adapted to local conditions and used flexibly.

UnitekFiber Solution supplies professional products and services of fiber Indoor/outdoor cables, Fiber cable management, high density datacom cabling, Fiber optical connectivity and PLC splitter and so on . We have mature production experience and strict product quality inspection. Our products and solutions are widely applied in 4G/5G, Data Center and Cloud Computing industry etc.

For the more information about ADSS cable parameters test, please contact us at sales@unitekfiber.com .We will try our best to support you.

+86-755-21034367